Sheet Metal Joggle - Web what is joggle forming. Joggle forming presses create multiple bends on sheet metal simultaneously. Web a joggle, often found at the intersection of stringers and formers, is the offset formed on a part to allow clearance for a sheet or another mating part. This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset. Web a joggle bend in sheet metal (at top of image) and a hand joggling tool joggling , [5] also known as joggle bending , is an offset bending process in which two opposite bends with equal angles are formed in a single. Note that closed hems, teardrop, and edge bead are all. Use of the joggle maintains the smooth surface of a joint or. Often, these bends are in opposite directions and less than 90°. Web with the new joggle command, complex joggles can be created on tabs and flanges. A joggle press works by clamping sheet.

Web a joggle, often found at the intersection of stringers and formers, is the offset formed on a part to allow clearance for a sheet or another mating part. A joggle press works by clamping sheet. Use of the joggle maintains the smooth surface of a joint or. This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset. Web a joggle bend in sheet metal (at top of image) and a hand joggling tool joggling , [5] also known as joggle bending , is an offset bending process in which two opposite bends with equal angles are formed in a single. Note that closed hems, teardrop, and edge bead are all. Joggle forming presses create multiple bends on sheet metal simultaneously. Web what is joggle forming. This is a cad setup for an open hem on two edges. Often, these bends are in opposite directions and less than 90°.

Web a joggle, often found at the intersection of stringers and formers, is the offset formed on a part to allow clearance for a sheet or another mating part. This is a cad setup for an open hem on two edges. Note that closed hems, teardrop, and edge bead are all. Use of the joggle maintains the smooth surface of a joint or. Web a joggle bend in sheet metal (at top of image) and a hand joggling tool joggling , [5] also known as joggle bending , is an offset bending process in which two opposite bends with equal angles are formed in a single. Web with the new joggle command, complex joggles can be created on tabs and flanges. This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset. Often, these bends are in opposite directions and less than 90°. Joggle forming presses create multiple bends on sheet metal simultaneously. Web what is joggle forming.

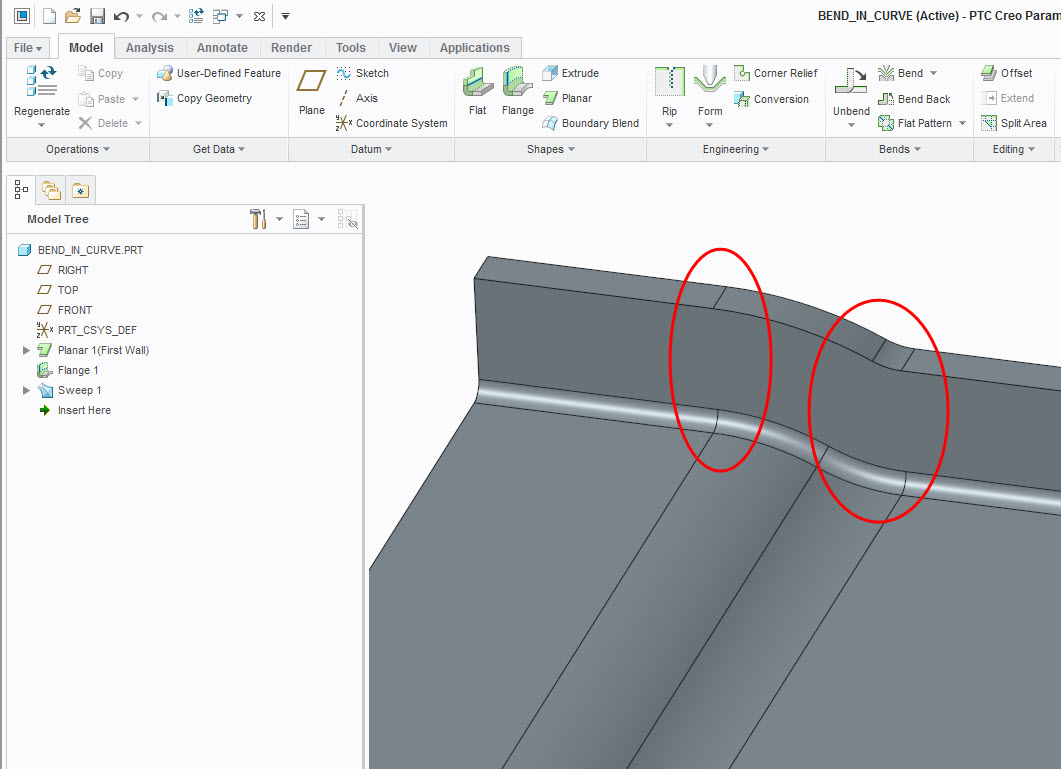

Solved Creo Sheetmetal Joggle Tangent Lines PTC User Community

A joggle press works by clamping sheet. This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset. Web with the new joggle command, complex joggles can be created on tabs and flanges. Web a joggle bend in sheet metal (at top of image) and a hand joggling tool joggling , [5] also.

RVZ Adjustable Joggle Tool YouTube

Joggle forming presses create multiple bends on sheet metal simultaneously. This is a cad setup for an open hem on two edges. Web what is joggle forming. Web with the new joggle command, complex joggles can be created on tabs and flanges. Note that closed hems, teardrop, and edge bead are all.

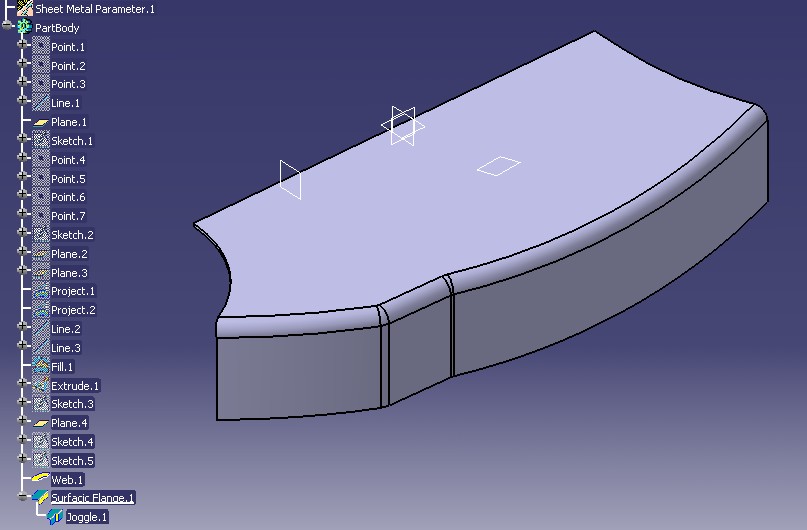

Creating and modifying a Joggle

This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset. Use of the joggle maintains the smooth surface of a joint or. Web a joggle, often found at the intersection of stringers and formers, is the offset formed on a part to allow clearance for a sheet or another mating part. Web.

Techniform Metal Curving Hot Joggle, Joggle, Hand Form, & Check and

This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset. Often, these bends are in opposite directions and less than 90°. Joggle forming presses create multiple bends on sheet metal simultaneously. Use of the joggle maintains the smooth surface of a joint or. Web what is joggle forming.

Joggled sheet metal brackets and their uses in UK industry

This is a cad setup for an open hem on two edges. Use of the joggle maintains the smooth surface of a joint or. Web a joggle, often found at the intersection of stringers and formers, is the offset formed on a part to allow clearance for a sheet or another mating part. Web with the new joggle command, complex.

OllieG's 914 Joggle Bends, Sheet Metal Brakes and other headaches..

This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset. Web with the new joggle command, complex joggles can be created on tabs and flanges. Joggle forming presses create multiple bends on sheet metal simultaneously. This is a cad setup for an open hem on two edges. Often, these bends are in.

OllieG's 914 Joggle Bends, Sheet Metal Brakes and other headaches..

This is a cad setup for an open hem on two edges. Use of the joggle maintains the smooth surface of a joint or. A joggle press works by clamping sheet. Web a joggle bend in sheet metal (at top of image) and a hand joggling tool joggling , [5] also known as joggle bending , is an offset bending.

Joggled sheet metal brackets and their uses in UK industry

Web with the new joggle command, complex joggles can be created on tabs and flanges. Joggle forming presses create multiple bends on sheet metal simultaneously. This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset. Web a joggle bend in sheet metal (at top of image) and a hand joggling tool joggling.

Techniform Metal Curving Hot Joggle, Joggle, Hand Form, & Check and

Web a joggle bend in sheet metal (at top of image) and a hand joggling tool joggling , [5] also known as joggle bending , is an offset bending process in which two opposite bends with equal angles are formed in a single. Joggle forming presses create multiple bends on sheet metal simultaneously. This allows the sheet metal parts to.

Folding sheet metal components with formed joggles using a CNC press

Joggle forming presses create multiple bends on sheet metal simultaneously. Web a joggle, often found at the intersection of stringers and formers, is the offset formed on a part to allow clearance for a sheet or another mating part. Web a joggle bend in sheet metal (at top of image) and a hand joggling tool joggling , [5] also known.

This Is A Cad Setup For An Open Hem On Two Edges.

A joggle press works by clamping sheet. Web a joggle bend in sheet metal (at top of image) and a hand joggling tool joggling , [5] also known as joggle bending , is an offset bending process in which two opposite bends with equal angles are formed in a single. Often, these bends are in opposite directions and less than 90°. This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset.

Joggle Forming Presses Create Multiple Bends On Sheet Metal Simultaneously.

Web with the new joggle command, complex joggles can be created on tabs and flanges. Web what is joggle forming. Note that closed hems, teardrop, and edge bead are all. Web a joggle, often found at the intersection of stringers and formers, is the offset formed on a part to allow clearance for a sheet or another mating part.